Farmer-to-bar

LEARN MORE ABOUT OUR PROCESSAll our partner farmers must complete an 8-16 week workshop on good agricultural practices and sustainable farming methods. Upon graduation, they are provided with farming tools and continuing support from our trainers.

Our farmers break open cocoa pods and select ripe and disease-free beans to continue to the fermentation process.

The cocoa beans are fermented for a period of up to 7 days. During fermentation, the flavour and aroma potential of beans develop, and bitterness is reduced

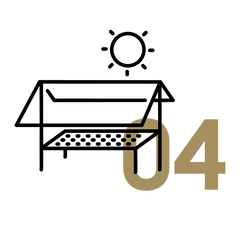

Our beans are naturally sun-dried for about 7 days. Sun drying further develops flavour prevention of the beans while preventing the development of off-flavours associated with artificial dryers. It is also during this process that moisture content in the beans is reduced to improve their storability.

Defective beans and non-cacao materials (like rocks and and leaves) are hand-sorted and separated, leaving only healthy cacao beans for the roasting process.

During roasting, the beans undergo the Maillard reaction, which brings out the flavours and aromas that characterise our chocolate.

The cocoa beans are broken into small pieces called nibs, and the shells are separated from the nibs during the winnowing process.

The nibs are ground into a paste called cocoa liquor and mixed with other ingredients such as cocoa butter and sugar. The mixture is refined for up to 48 hours to form a silky smooth chocolate.

The finished chocolate is tempered to allow the formation of the right cocoa butter crystals to give it a smooth and shiny appearance, and then poured into our bar moulds.

Once solidified, our bars are moved from their moulds and meticulously hand-wrapped in our distinctive packaging.